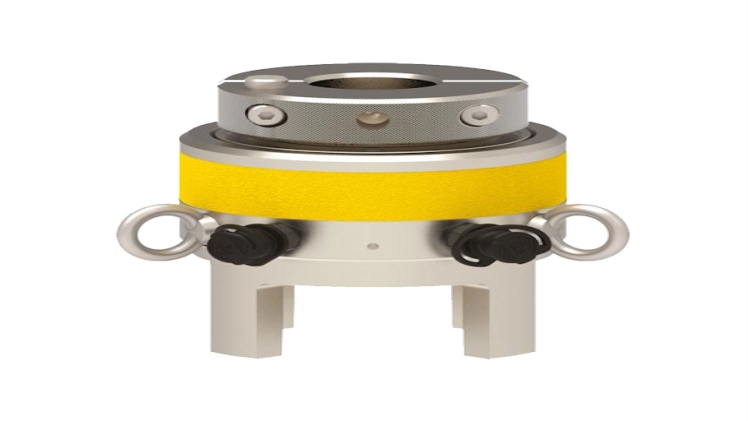

The EAJ Series Subsea Hydraulic Bolt Tensioners are a cutting-edge option for efficient bolt tensioning in underwater applications. Extreme undersea circumstances won’t deter these tensioners from ensuring safe and dependable connections. Their small size makes it simple to integrate them into diverse subsea projects, such as underwater pipelines and offshore oil rigs.

Benefits and Features

The EAJ Series Tensioners have cutting-edge features, including corrosion-resistant materials and a high-pressure hydraulic system, that enable them to operate better and last longer. By enabling uniform bolt loading, the tensioners reduce the possibility of leaks and structural failures. Additionally, their precise and quick tensioning method greatly reduces maintenance downtime.

Operation Guide

Use these easy procedures to operate EAJ Series Subsea Hydraulic Bolt Tensioners. Ensure the equipment is assembled properly, and the hydraulic pump and tensioner are compatible. The bolts should then be evenly tensioned by inserting the tensioner between the bolted joints and gradually applying hydraulic pressure. Monitor the pressure gauge to avoid overloading and guarantee proper tensioning.

Installing Procedures

For bolt tensioning to be successful, installation must be done correctly. First, thoroughly clean the bolt surfaces and flange to remove debris and impurities. Applying the necessary lubricant before installing the EAJ Series Tensioner on the bolt. Following the recommended torque settings, carefully tighten the tensioner nut. For each of the joint’s bolts, repeat the procedure.

Tips for Maintenance

The EAJ Series Subsea Tensioners’ lifetime is increased by routine maintenance. Regularly inspect your equipment to look for wear, damage, or leaks. Subsea tensioners demand special attention due to their exposure to harsh underwater conditions. Maintain the tensioner’s parts’ cleanliness and lubrication. Any broken parts should be replaced right away to prevent operational disruptions. Keep the tensioners in a dry, regulated atmosphere to avoid corrosion, especially in subsea environments. Adhering to these maintenance practices ensures the longevity and reliable performance of EAJ Series Subsea Hydraulic Bolt Tensioners.

Assess Component Integrity

If there are problems while tensioning, thoroughly troubleshoot the tensioner system. Look for any hydraulic fluid leaks, broken seals, or defective parts. Check the connections and hydraulic pump for proper operation. For particular issues and answers, consult the manufacturer’s troubleshooting manual.

Safety Measures

The risks of using subsea equipment, such as long piston stroke EAJ Series Tensioners, is inherent. Put safety first by using the proper personal protection equipment (PPE) and employing tools with a license. Teach staff how to use and handle EAJ Series Tensioners, including properly understanding the long piston stroke’s significance. Never apply more pressure or torque than is advised to avoid equipment failure and potential mishaps. By prioritizing safety protocols and providing adequate training, operators can mitigate the risks associated with subsea operations and ensure a secure working environment for all involved.

Applied Fields

The EAJ Series Tensioners are frequently used in subsea projects, such as underwater construction, offshore wind farms, and oil and gas exploration. These tensioners provide dependable bolted connections for vital subsea infrastructure, assuring operational effectiveness and safety in difficult circumstances.

Comparative analysis

EAJ Series Subsea Hydraulic Tensioners have several benefits compared to conventional bolt tensioning techniques. Their small size enables access to confined locations, and the hydraulic mechanism ensures controlled and exact tensioning. Additionally, they are perfect for lengthy underwater exposure due to their corrosion-resistant materials.

Performance tips

Follow the right installation and maintenance procedures to get the most out of the EAJ Series Tensioners. To achieve precise pressure measurements, calibrate the hydraulic pump regularly. Consider utilizing compatible add-ons like reaction nuts and bridge adapters for greater versatility. To maximize tensioning effectiveness, give operator training priority.

In conclusion, the success of subsea projects depends on understanding how to operate and maintain EAJ Series Subsea Hydraulic Bolt Tensioners. According to the advised procedures and safety recommendations, operators can profit from their remarkable features, dependable performance, and lifespan in testing underwater settings.

Innovations and improvements

Cutting-edge improvements and innovations continue to be incorporated into the EAJ Series Subsea Hydraulic Bolt Tensioners. Manufacturers constantly explore and adopt new materials and technologies to improve their performance and dependability. Hydraulic system improvements have made tensioning more accurate and effective, decreasing project downtime and enhancing safety. Additionally, design improvements have increased accessibility in constrained subsea regions, broadening the uses for these tensioners. As technology advances, users may anticipate more advanced features, increased durability, and improved overall performance from the EAJ Series Subsea Hydraulic Bolt Tensioners.